Changes to Plenco Physical Inventory

The Future has arrived!

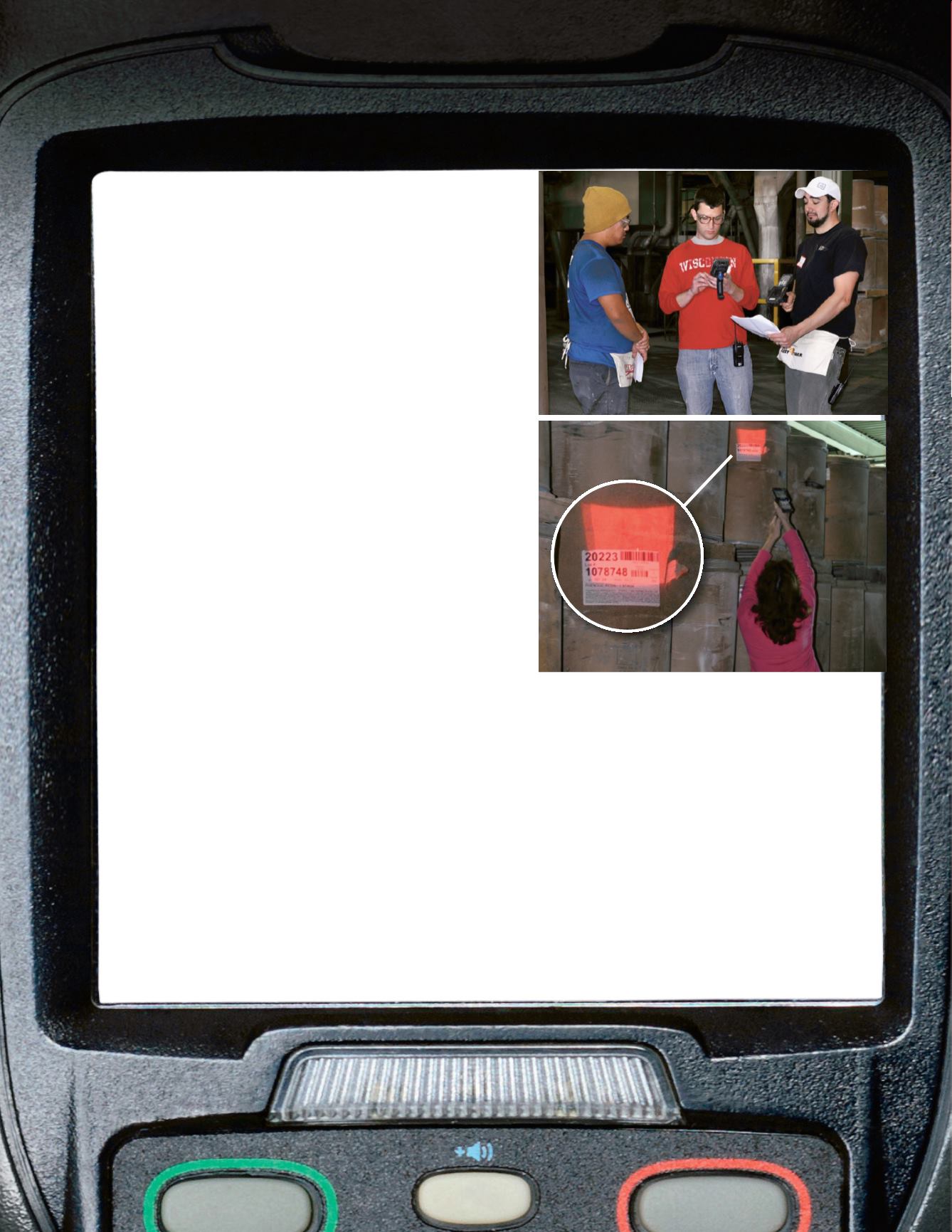

Top: Tony Lee, Todd Gehri and Dino Castillo setting

scanners up for Physical Inventory. Bottom: Scanning in

action, Chris Cadotte shows us how it’s done.

P

erhaps it’s not as exciting as “Breaking News” from

CNN, but the Physical Inventory process using

hand-held scanners has arrived at Plenco, as

Wayne

Pakkebier

(Production Control) predicted a year ago in

PlastiScope21’s

in-depth article on the subject.

Wayne looked forward to the day when volunteers would

use hand-held scanners rather than clipboards and paper

tickets, but that day came sooner than expected.

When our story ran in 2014, Wayne was unsure how

much time complete automation would take, but he thought

it might be a couple years at least. Only a year later,

Plenco’s tedious but important task of inventory has been

automated.

Hand-held scanners, 30 in all, were the biggest change

volunteers noticed in 2015. Seventeen teams of two people

and 11 coordinators scanned 2,400 audit tags in record time;

most teams wrapped up before 10:00 am on the day of

inventory.

Andrea Voss

(Accounting) told

PlastiScope21

,

“Days, maybe even weeks, were saved in time and effort,

both up front preparation and on the backside following

inventory.”

Todd Gehri

(Engineering) worked with Plenco’s IT

department to customize an already existing cycle count

program to meet specific Physical Inventory needs.

Lessons learned testing the software at BMC were applied

to creating and troubleshooting the software.

In preparation for the use of a computerized inventory

reporting system, Plenco’s IT department worked with

electricians to run conduit, wiring and Wi-Fi systems

throughout the plant. Despite Todd’s fears of power outages

or server connectivity glitches, no technical problems

occurred during Physical Inventory.

The entire team responsible for organizing Plenco’s

annual exercise agreed they couldn’t be happier with the

new system. Andrea said, “Many of the volunteers had no

prior scanning experience, but they were all good sports,

and we received no negative feedback from them. The end

results look awesome!”

In addition to the people who show up on inventory day,

the team thanks all those who prepared and organized for

inventory weeks ahead of time.

The scanners allowed for real-time results

almost immediately, making catching and

correcting any mistake easier. Errors were few

because of safeguards put in place to ensure

ease of use for the volunteers and accuracy for

the team reviewing and processing the data

collected.

“Now the fear factor is gone. It was a very

positive experience, and we are always looking

for new volunteers,” Wayne said. If you would

like to be one of these new volunteers and take

a scanner for a spin, mark your 2016 calendar

for the first Saturday in November.

11

Hand-Held Scanners Replace Paper Tickets

For Plenco’s Annual Physical Inventory