20

PLENCO CSR Initiative

The Importance of

Engineered Maintenance

In Plenco’s Highly Engineered Plants, with High-Tech Equipment, Operated by

Highly Skilled Personnel, ‘Engineered Maintenance’ is Imperative

As indicated by its corporate name, at the core

of Plenco is

engineering

. It crosses every function-

ality of the company and is a major reason for the

company’s innovative products and cutting-edge

processes.

It also guides our evolution in environment, health

and safety policies and practices.

Well-developed preventive maintenance programs

provide a safe work environment while helping

to ensure consistent, on-time delivery to Plenco

customers. Our first and foremost priority is to pro-

vide our employees a safe and healthy workplace.

Plenco’s combined Engineering and Maintenance

Departments represent the largest operational

group in the company. The work of the joint engi-

neered maintenance team reflects our philoso-

phy that

“doing it ourselves, and doing it right”

is preferable to outsourcing critical services and

more effective in assuring employee safety and the

integrity of Plenco’s buildings and equipment.

The structure of today’s maintenance operations

date back to the 1960s when process equipment

was built, customized and installed mainly by

Plenco’s in-house engineers, electricians and

safety professionals as the company expanded its

operations.

That proven approach exists today, with technical

changes reflecting new equipment and methods

that have become accessible over the last 50 years.

The joint team works together, onsite and avail-

able 24/7 to ensure that production runs smoothly,

efficiently and reliably to meet customers’ quality

and delivery expectations.

To perpetuate this philosophy, we take advantage

of evolving educational opportunities to provide

our technical staff with cutting-edge training at

technical colleges near our facilities. As a result,

employees can increase their knowledge and skills

and advance in their job positions at Plenco.

actions

speak

louder...

We are all ‘Students and

Teachers’ at Plenco

Every day at Plenco, we are learning from each

other, and teaching each other, in one way or

another. Plenco sees education as a cornerstone

of success professionally and personally, and we

encourage learning at every stage of our lives.

One example is our apprenticeship program in

cooperation with local and state higher education

technology institutes and colleges.

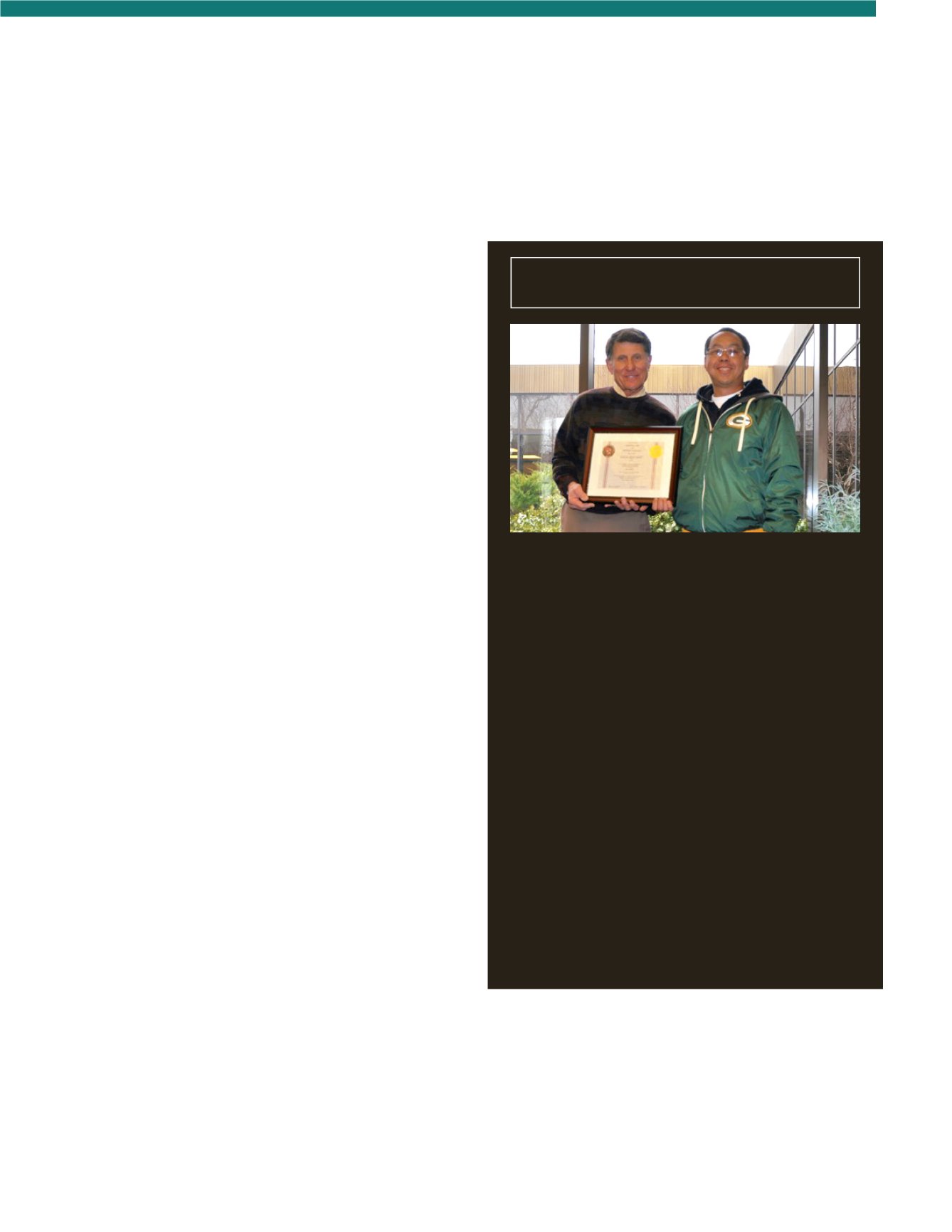

Case in point: Pao Yang began his career at

Plenco in 1993 as a Bag Cleaner and Repairer

in the Maintenance department. He went on to

become a resin grinder and packer, resin QA Tech-

nician, and Finisher and Maintenance Mechan-

ic. In 2015, he earned a Millwright Journeyman

certificate from the State of Wisconsin after four

years of schooling and a minimum of 7,500 hours

of on-the-job training. He was recognized for his

achievements by Plenco President and CEO Mike

Brotz in this photo.

This policy is

proactive

in designing equipment,

building customized production processes, and

executing preventative maintenance, while it is

reactive in solving unexpected maintenance chal-

lenges.